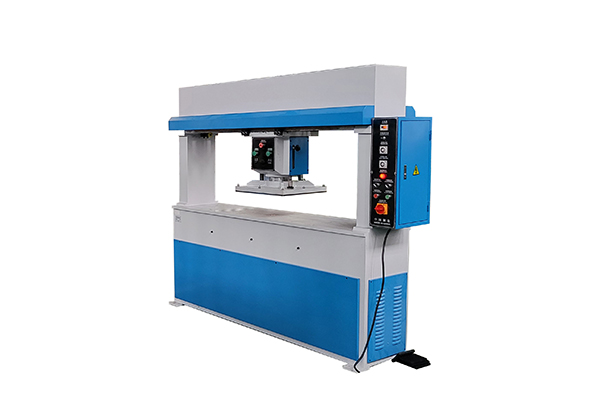

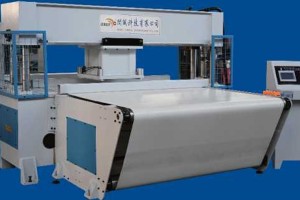

HCLL3-300 Cutting Head Moveable Hydraulic Die Cutting Machine

Standard Configuration

● Intelligent fabric Correction

● Intelligent Fault Detection

● Intelligent Prompt of Cutter Replacement

● Software Control for thermal Shrinkage of fabrics

● Intelligent film-re-covering device

● Intelligent dust collection and cleaning device

● Automatic Sharpening and punching

● Absorption and bed replacement function

● Multiple gears of air exhaust items

● Automatic Locking of Cutter head

Application

Toys

Car Interiors

Bags

Home Interiors

Outdoor Products and other materials different kinds of cutting

Features

1、The Automatic Computer Cutting Machine Reduces labor costs, automatic computer cutting machine in the same time can complete the workload of 10 manual cutting workers.Improve production efficiency, can improve the production efficiency of enterprises about 10%-20%.

2、The Automatic Computer Cutting Machine saves the fabric, the use of CAD automatic discharge, than manual discharge to save and improve efficiency, can save about 1%-3% of the fabric,improve safety, automatic computer cutting bed according to the layout diagram cutting, workers only need to control the machine at the side, high safety factor, avoid manual cutting safety accidents.

3、The Automatic Computer Cutting Machine Improves the management level, reduce the shirking of responsibilities and conflicts between cooperative departments, and improve the performance of middle managers; Avoid the influence of human factors on production schedule.

Detail Drawing

Advantage

1、Beautify the environment, improve the corporate image, cutting cloth scraps through special pipes out of the outdoor, so that cutting environment clean and tidy.

2、Automatic Rewinding and and secondary laminating device can reduce adsorption power, reduce consumption cost, enhance adsorption strength and improve fabric precision.

3、By adopting computer design and automatic typesetting, it saves raw materials.

4、The section cut by the facility has high precision, and the sections can be directly sewed without any trimming by the lathe workers, which effectively increases the sewing efficiency of the lathe workers.

FAQ

Q:What are your prices?

A:Our prices are subject to change depending on supply and other market factors. We will send you an updated price list after your company contact us for further information.

Q:Do you have a minimum order quantity?

A:Yes, we require all international orders to have an ongoing minimum order quantity. If you are looking to resell but in much smaller quantities, we recommend you check out our website.

Q:Can you supply the relevant documentation?

A:Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

Q:What is the average lead time?

A:For samples, the lead time is about 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment. The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.