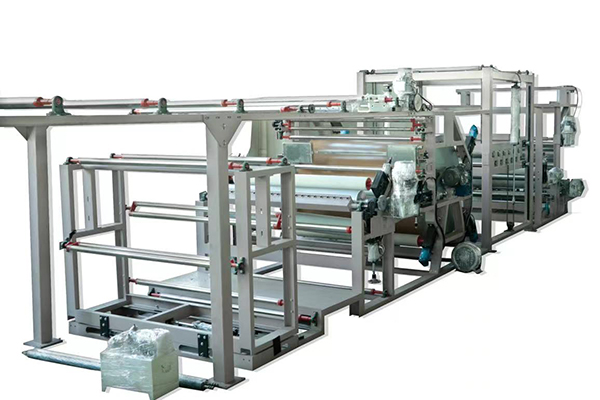

OEM Customized Roll Lamination Machine - High Efficiency Vertical Belt Water Glue Base Laminating Machine For Shoes Textile Fabric Eva Sponge – Yuanhua

OEM Customized Roll Lamination Machine - High Efficiency Vertical Belt Water Glue Base Laminating Machine For Shoes Textile Fabric Eva Sponge – Yuanhua Detail:

Application

| Model | YH-002 |

| Power | 380V/220V |

| Weight | 3000kg |

| Speed | 0-60m/min |

| Standard Roller Size | 1500mm*1800mm |

Feature

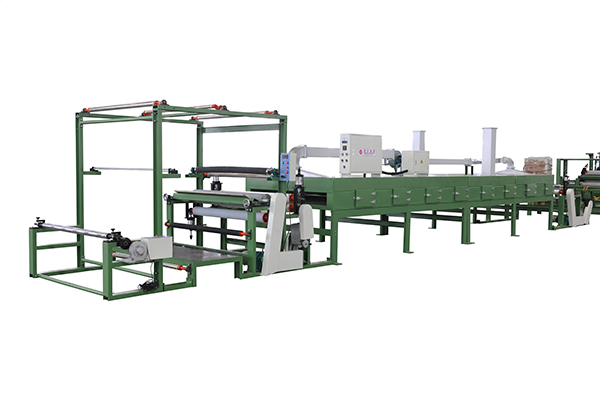

1.The Vertical Belt Water Glue Laminating Machine uses water-based glue or the white latex.

2.The Vertical Belt Water Glue Laminating Machine improves the quality of the products greatly, save cost.

3.The Vertical Belt Water Glue Laminating Machine has vertical structure, low breakdown rate and long service time.

4.Equipped with high quality heat resistance net belt to make sure the laminated materials contact closely with the drying cylinder, that can improve the drying effect, and make the laminated product soft, and strengthen adhesive fastness.

5.This leather laminating machine has two sets of heating system, user can select one set heating mode or two sets, to reduce the energy consumption and lower costs.

6.The Surface of heating roller is coated with Teflon paper in order to efficacious prevent the unevenly heating.

7.For clamp roller of the Vertical Belt Water Glue Laminating Machine, both hand wheel adjustment and the pneumatic control are available.

8.Equipped with automatic infrared centering control unit, which can effectively prevent the net belt deviation, and ensure the net belt service life

9. Customized manufacturing is available, we can customized the machine structure based on the feature of customers’ materials and customers’ need.

10.The Vertical Belt Water Glue Laminating Machine has very low maintenance cost and simple to maintain. And it is very easy to operate.

How to maintain the machine

1.The reducer should be replaced with lubricating oil every 6 months.

2.The Engine of this laminating machine should be replaced with lubricating every 12 months.

3.The chain needs to be properly lubricated and tensioned.

4.The gluing parts must be cleaned after use.

Application

Toys

Bags

Clothes

Carpets & Home Interiors

Different Home interiorproduct Laminating

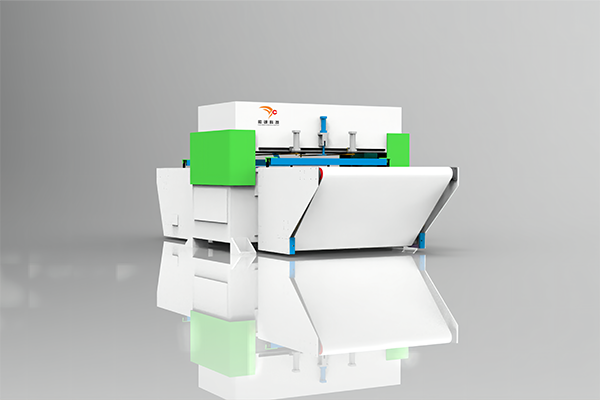

Product detail pictures:

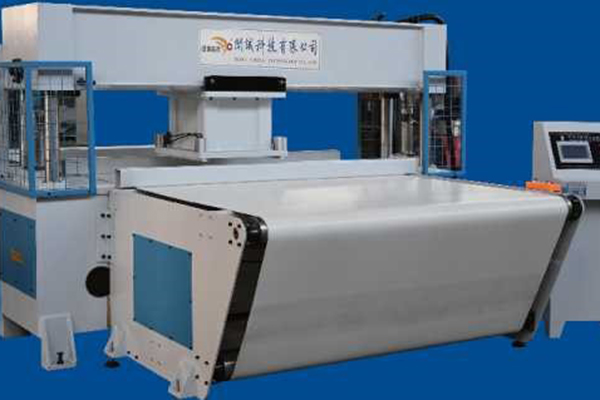

Related Product Guide:

With state-of-the-art technologies and facilities, strict good quality regulate, reasonable cost, exceptional assistance and close co-operation with prospects, we're devoted to supplying the top benefit for our customers for OEM Customized Roll Lamination Machine - High Efficiency Vertical Belt Water Glue Base Laminating Machine For Shoes Textile Fabric Eva Sponge – Yuanhua , The product will supply to all over the world, such as: Madras, UK, Bogota, All these products are manufactured in our factory located in China. So we can guarantee our quality seriously and availably. Within these four years we sell not only our products but also our service to clients throughout the world.

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.