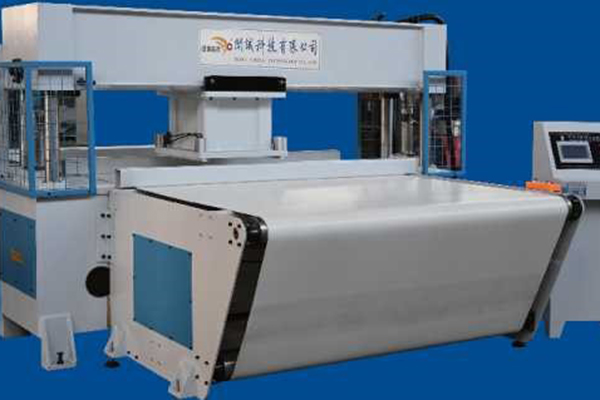

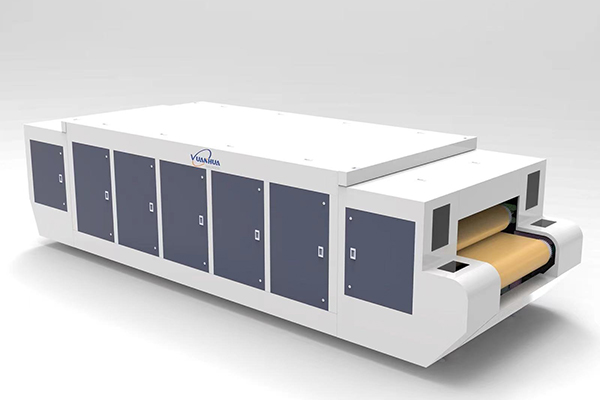

Manufactur standard Flm Non Woven Laminating Machine - Automatic YH-001 Double Belt Flat Bed Laminating Machine For Fiber Special Materials – Yuanhua

Manufactur standard Flm Non Woven Laminating Machine - Automatic YH-001 Double Belt Flat Bed Laminating Machine For Fiber Special Materials – Yuanhua Detail:

Feature

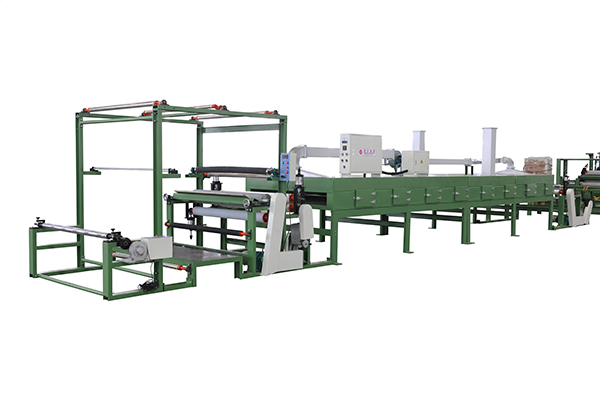

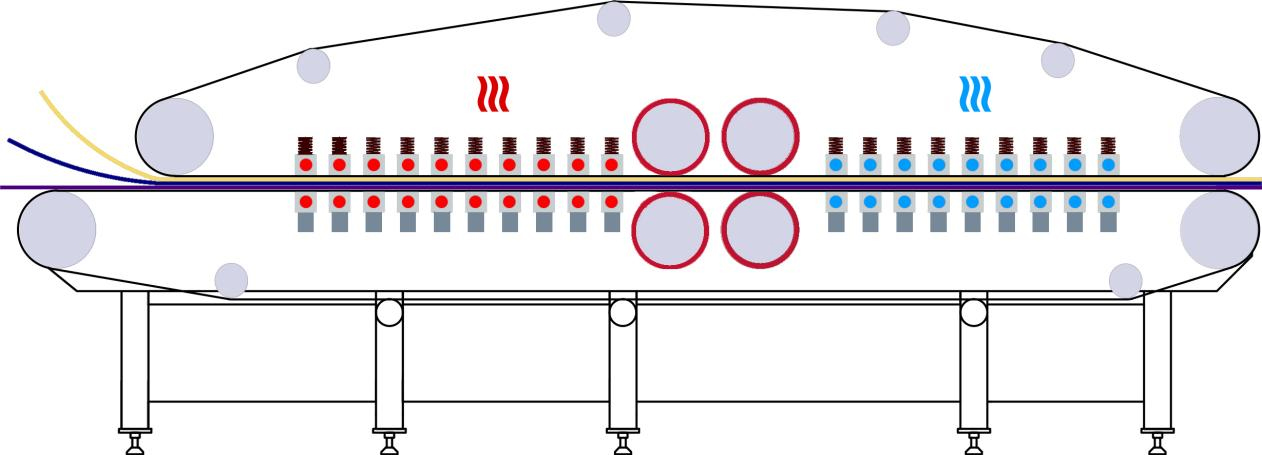

The pressure of Double belt flat bed laminating machine is transferred by two conveyor belts up and down and the contact is heated and cooled

While the system is integrated, the composite material will heat evenly because with a long enough heating zone, the material will be perfectly compounded and have high strength, materials can be laminated together after heating and passed through the pressure roller to adjust the material height, in order to ensure the composite strength, before the material out of the conveyor belt, the front is cooled through the gaps between the conveyor belts and the precise height adjustment section, even 150mmd rigid sheet can be composite.

|

Working Width |

1800mm/2000mm/2200mm Customized |

|

Height |

0-100mm |

|

The Length Of Heat Area |

1500mm(Customized) |

|

The Lenght Of Cooling Area |

1500mm(Customized) |

The Heating system of Double Belt Flat Bed Laminating Machine is divided into 18 zones that can be separately control by PLC system. Which there are 9 separately zones in the top heating plate and 9 separately zones in the bottom heating plate.

The space between Flat Bed Machine top plate and bottom plate is adjustable.

The height of the upper conveyor belt system can be precisely raised in order to adjust the spacing between the upper and lower belts, so that it is consistent with the thickness of the material.

The Laminating Process Of Small Flame Laminating Machine

1. Without traditional seam broken connection state, strong adhesion, clear embossing that the ultrasonic embossing machine has the a better embossing effect, and more beautiful products;

2. After processing, the waste products have no pinhole and no seepage, and have more waterproof and heating effect;

3. The Ultrasonic Embossing Machine is easy to change the mold that can sew the kaleidoscope, complex discontinuity and symmetry patterns, according to customer needs to develop a variety of patterns;

4. The Ultrasonic Embossing machine has a high degree of automatic intelligence, the infrared automatic edging system can automatically correct each layer of materials, so that the upper and lower materials in the suture process always keep aligned, low processing loss, more smooth and stable products.

Multiple ways of Laminating

● Glue Powder Laminating

● Hot Melt Film Laminating

● Soluble Adhesive Laminating

● Solid Glue After Melting Laminating

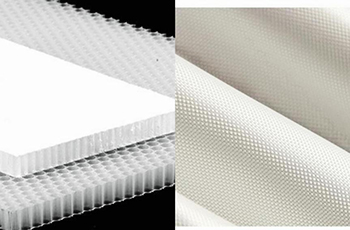

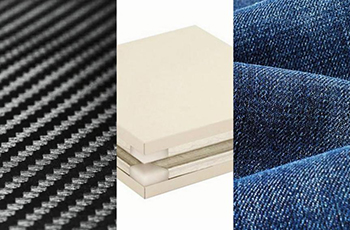

Application

Carbon fiber, ceramic fiber, glass fiber, Aerogel blanket,sound insulation absorbent cotton, aramid fiber, cotton,Aramong, honeycomb panel, Graphene, Bulletproof material, and other kinds of Laminating. All of them can be laminated by the Double Belt Laminating Machine.

● Medical Industry

Film Laminate, Material Compressed…

● Automobile Industry

Battery insulation Laminating ,Aerogel Blanket Laminating…

● Material Lamination

Fiber Laminate, Multiple Material Laminate…

● Filter Industry

Activated Carbon Filter, Non-woven material Processing…

● Military Project

Armor Material Laminating, Battle Dress Uniform Bonding …

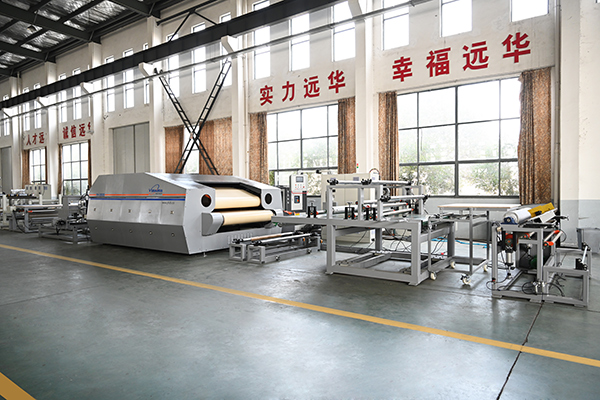

Product detail pictures:

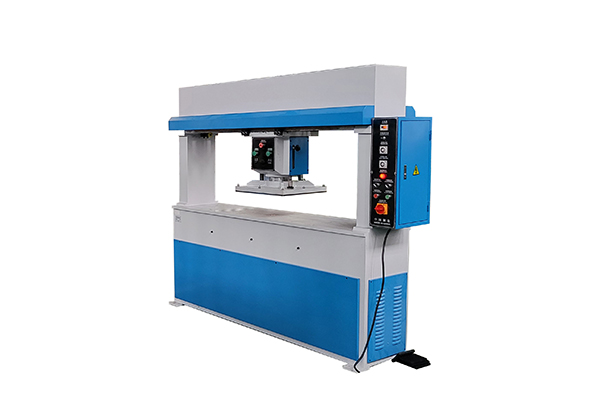

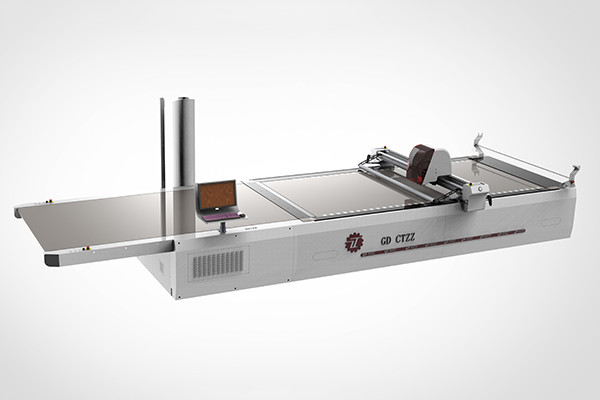

Related Product Guide:

With this motto in mind, we've turn into one of quite possibly the most technologically innovative, cost-efficient, and price-competitive manufacturers for Manufactur standard Flm Non Woven Laminating Machine - Automatic YH-001 Double Belt Flat Bed Laminating Machine For Fiber Special Materials – Yuanhua , The product will supply to all over the world, such as: Manchester, Denmark, Seattle, Our staffs are rich in experience and trained strictly, with qualified knowledge, with energy and always respect their customers as the No. 1, and promise to do their best to deliver the effective and individual service for customers. The Company pays attention to maintaining and developing the long-term cooperation relationship with the customers. We promise, as your ideal partner, we'll develop a bright future and enjoy the satisfying fruit together with you, with persisting zeal, endless energy and forward spirit.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!