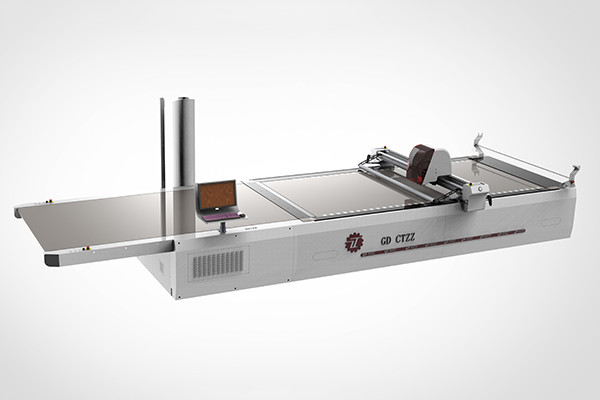

Fixed Competitive Price 3d Fiber Laser Cutting Machine - XCLP3 Series Auto-balance Precision Four-column Hydraulic Plane Die Press Cutting Machine – Yuanhua

Fixed Competitive Price 3d Fiber Laser Cutting Machine - XCLP3 Series Auto-balance Precision Four-column Hydraulic Plane Die Press Cutting Machine – Yuanhua Detail:

Usage or Featuresof of Die Press Cutting Machine

The Hydraulic Plane Die Press Cutting Adopts double oil cylinder,precise double-crank connecting rod mechanism,which can guarantee that the cutting depth at every cutting position is same.

With special setting mechanism,and equipped with die cutter and cutting depth setting,the travel adjustment is simple and accurate.

The pressing board of cutting carries out slow cutting when it contacts the die cutter,which can make that there is no size error between the uppermost layer and lowermost layer of cut materials.

All sliding parts of the Hydraulic Plane Die Cutting are lubricated with oils supplied by the hydraulic system guarantees machine precision and prolongs service life of cutting machine.

Production Engineering of Die Press Cutting Machine

1. The production of cutting machine is first to select the size and thickness of the table size and tonnage.

2. Cut the selected materials and various parts.

3. Welding of the machine frame body.

4. Finishing machine frame body, spare parts.After the machining center is processed, the main surface of the cutting machine must be carefully ground to ensure the planarity.

5. Processing of finished products to the drill bed to make all the installation screw holes, iron cut blow clean.

6. Select high-quality atomic ash and paint polished and smooth spray paint treatment.

7. Assembly master and installation.Balanced debugging during installation, pressure distribution instrument detection and running speed detection of feeding mechanism.

8. The inspector shall check whether there are any problems with each part and pass the acceptance inspection.

9. Oil and power to clean the surface oil

10. Finally seal the machine, package.

Leading Feature of Die Press Cutting Machine

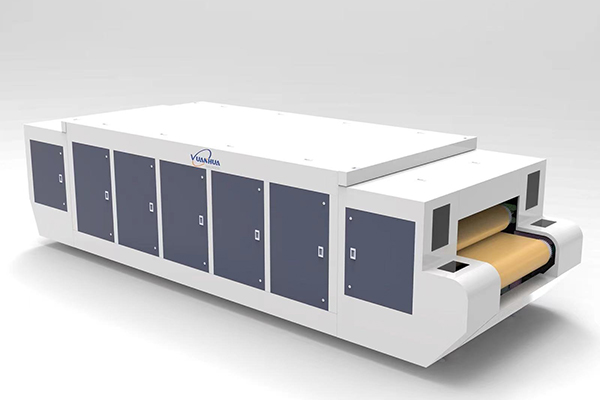

● Computer control system, touch screen display, simple, fast and accurate operation.

● Cutting balance is good, can reduce the loss of cutting steel mold and cutting board, cutting edge has a better effect, can more reduce the consumption of cutting board.

● The fixed clamp device of the knife mold is convenient and quick.

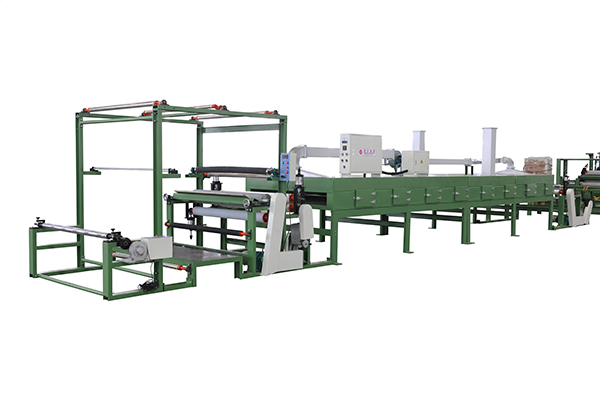

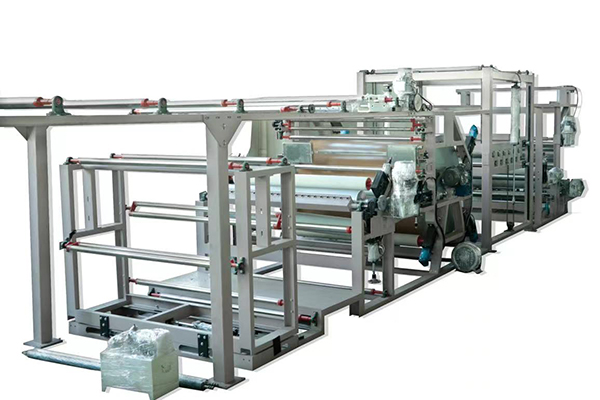

● The input and output of materials are transported on the conveyor belt, and the die cutting of the material is also automatically completed on the conveyor belt.

● The cutting machine is equipped with a blocking mechanism, which can effectively improve the cutting accuracy and efficiency.

● Hydraulic system: double cylinder working at the same time, the fuel tank is equipped with cooling device, oil storage device, oil filter device, mechanical is equipped with pressure display device.

● Automatic equipment machinery is equipped with automatic feeding system.

Scope of Application of Cutting Machine

Cutting machine is suitable for pearl cotton foam materials, cardboard, textile, leather products, plastic materials, floor materials, pressing materials, glass fiber, cork and other materials, especially for a large area of rolling products.cutting machine can provide good cutting accuracy action, and large cutting capability output.

Technical Specification of Cutting Machine

| Model | XCLP3-30 | XCLP3-35 | XCLP3-40 | XCLP3-50 | XCLP3-60 | XCLP3-80 | XCLP3-100 | XCLP3-150 |

| Maximum Cutting Force | 30T | 35T | 40T | 50T | 60T | 80T | 100T | 150T |

| Tension distance | 50-200mm/50-245mm | |||||||

| (mm) | ||||||||

| Cutting area | 1600*550 | 1600* | 1600*610 | 1600*800 | 1600*900 | 1600*900 | 1600*900 | 1600*1000 |

| (mm) | 610 | 1400*610 | 1400*800 | 1400*900 | 1400*900 | 1400*900 | 1400*1000 | |

| Motor power | 2.2 | 2.2 | 3 | 8 | 5.5 | 7.5 | 7.5 | 11 |

| (kW) | ||||||||

| Motor supply | 3*440/415/400/380/220V,50/60Hz | |||||||

| Machine weight | 1700 | 1900 | 2300 | 3800 | 4800 | 6300 | 7800 | 10000 |

| (kg) | 2000 | 3600 | 4600 | 6100 | 7600 | 9500 | ||

Made to order for your special specitications.For example,the cutting force,cutting area feeding device,special stroke.

Product detail pictures:

Related Product Guide:

Trustworthy good quality and excellent credit score standing are our principles, which will help us at a top-ranking position. Adhering towards the tenet of "quality first, buyer supreme" for Fixed Competitive Price 3d Fiber Laser Cutting Machine - XCLP3 Series Auto-balance Precision Four-column Hydraulic Plane Die Press Cutting Machine – Yuanhua , The product will supply to all over the world, such as: Greek, Australia, Georgia, The quality of our products is equal to OEM's quality, because our core parts are the same with OEM supplier. The above products have passed professional certification, and we not only can produce OEM-standard products but we also accept Customized Products order.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.