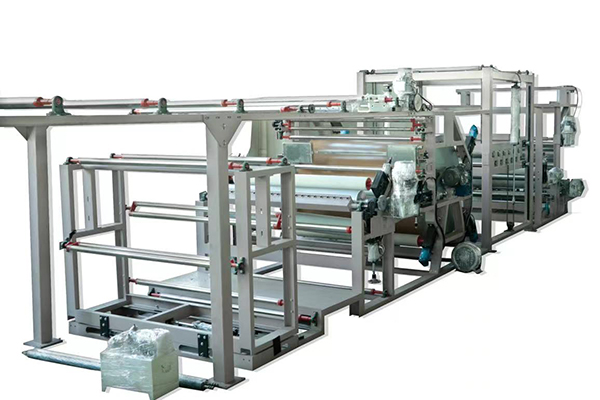

Factory wholesale Vacuum Laminating Machine - High Efficiency PU Oil Glue Base Laminating Machine for Sponge Fabric Textile Leather Foam Nonwoven Film – Yuanhua

Factory wholesale Vacuum Laminating Machine - High Efficiency PU Oil Glue Base Laminating Machine for Sponge Fabric Textile Leather Foam Nonwoven Film – Yuanhua Detail:

Application

There are many kinds of materials that PU oil Base glue Laminating machine can do , especially suitable for cloth, wool and wool, cloth leather, cloth paste paper, sponge stick cloth, sponge stick leather, stick fabric double-sided or four-sided elastic knitting fabric. Suitable structure can be selected according to different materials. Parts can be added or removed according to the properties of different materials. Suitable for the combination of water soluble and solvent binder coating to achieve the function of an all-in-one machine. The amount of coating and coating style can be adjusted according to the material and actual needs. Roller heating can be done by electricity, steam or thermal oil. The width of the roll surface of the machine can be specified according to the maximum width of the actual material and the whole machine system, and can be operated by the intelligent PLC program touch screen or mechanical operation.

|

Model |

YH-012 |

|

Power |

220V/380V |

|

Speed |

0m/min-60m/min |

|

Weight |

7000kg |

The Laminating Process Of Small Flame Laminating Machine

1.Based on the conventional glue point compounding machine, the machine has been upgraded with the functions of automatic deviation correction, automatic centering, automatic opening, automatic blowing of waste edges, etc., so that the composite material has the advantages of even glue coating, flat, no tensile deformation, no foaming, no wrinkle, soft, breathable, good performance, and neat winding.

2 Fabrics and double-sided or four-sided elastic knitted non-woven fabric and leather sponge and flannelette sponge and leather coating compound materials;

3 Rewinding and rewinding can be selected according to different materials;

4 according to the characteristics of different materials, some devices can be added or reduced;

5 Suitable for water-soluble and solvent-based adhesive coating compound, to achieve multi-purpose function of one machine

6 glue amount and glue style according to the material and actual situation

7 Main Heat Roller heating can be carried out by means of electric steam or heat conduction oil

8.The width of the roller surface can be specified according to the large width of the actual material

9.The whole system of this laminating machine can use intelligent PLC program touch screen or mechanical operation control

|

Dimension |

7800mm*1800mm(Customized)*2200mm |

|

Weight |

7000kg |

|

Power |

60kw |

Toys

Bags

Textile

Outdoor Products Laminating

Different Home interiorproduct Laminating

Car Interiors Laminating

Die Papers- Nusing Pad Laminating

Product detail pictures:

Related Product Guide:

We have the most advanced production equipment, experienced and qualified engineers and workers, recognized quality control systems and a friendly professional sales team pre/after-sales support for Factory wholesale Vacuum Laminating Machine - High Efficiency PU Oil Glue Base Laminating Machine for Sponge Fabric Textile Leather Foam Nonwoven Film – Yuanhua , The product will supply to all over the world, such as: Ecuador, Haiti, Albania, We hope we can establish long-term cooperation with all of the customers, and hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need!Welcome all customers both at home and abroad to visit our factory. We hope to have win-win business relationships with you, and create a better tomorrow.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!