100% Original Factory Duplex Lamination Machine - High Efficiency Filter Material laminating machine for Filter Bag Dust Bag – Yuanhua

100% Original Factory Duplex Lamination Machine - High Efficiency Filter Material laminating machine for Filter Bag Dust Bag – Yuanhua Detail:

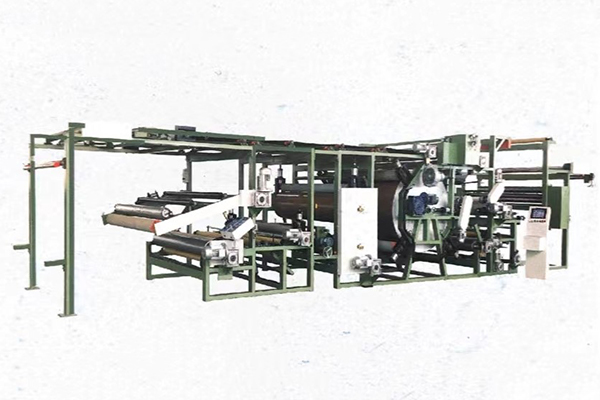

Hair drying, hot rolling, impregnation, drying, film coating, silicone coating and other sets of finishing equipment

Characteristics of high temperature filter bag laminating machine

Product good filter performance, strong wear resistance, high temperature resistance characteristics, greatly prolong the service life of the filter bag, is the ideal equipment for high-grade filter materials.

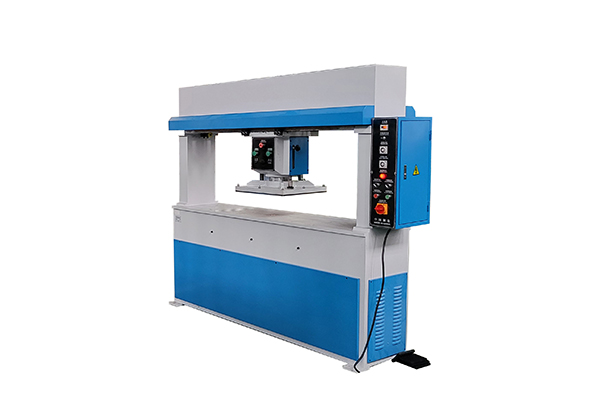

The appearance of high-grade atmosphere, the high and low structure of the platform considering workers operation and cleaning convenient design, multi-mode computer touch screen (HD), the platform is surrounded by silicone sealing edge, chromium nickel wire heating tube, Japan Mitsubishi PLC control, Yadk pneumatic components, plus aluminum exhaust heating, German constant temperature system, low power consumption.

High and low pressure point shock adsorption, high pressure pulse action, low pressure is used to draw the negative pressure, and finally use the point shock function bit by bit to complete the final adsorption, the machine pressure than the large negative pressure fully twice, adsorption effect is good, not easy to break the skin, high success rate, rest assured to use.

Application industry of high temperature filter bag laminating machine

Application of high temperature filter bag laminating machine

Polyester weaving, polyester acupuncture felt, high temperature resistant acupuncture felt, glass fiber woven and polytetrafluoroethylene (P TFE)

Microporous film is coated by high temperature and high pressure and adhesive.

Products through hair burning, pressing, coating, dipping, film mulching and other processes, so that each square filter material is through high temperature thermal setting treatment, to ensure the size stability of the filter material

Technology of high temperature filter bag laminating machine

1. Compress

Make the filter material surface smooth, smooth, uniform thickness, easy to clear ash; ensure that the dust is not easy to enter the deep filter material, improve the service life of the filter material

2. Burn hair

Use gas to burn the surface cilia, improve the surface structure, conducive to clear ash.

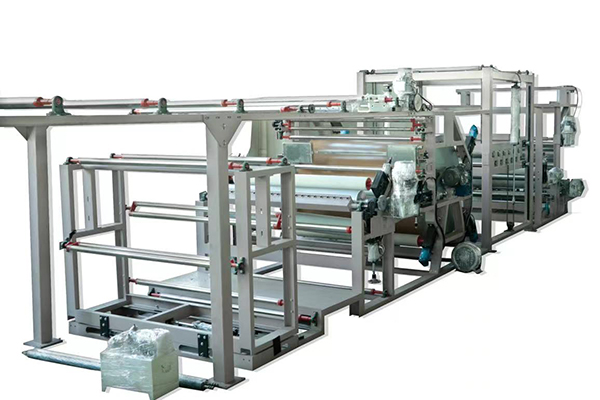

3. Cover the film

Thermal binding-first burn the filter material, then the film and the filter material through a series of pressure rollers, the two combined under the combination of pressure and temperature.PTFE film acts as a disposable dust layer, retaining all the dust on the membrane surface. The film has smooth surface, excellent chemical stability, heat and corrosion resistance, and good ash removal performance

4. PTFE immersion stain

Polytetrafluoroethylene emulsion is a neutral organic solvent, solid content of 60%, surface treatment agent, acid resistance, high temperature resistance, filter material by tetrafluoride treatment, anti-corrosion of SO2, SO3 and other acid gases.Improve the corrosion resistance of glass fiber felt.Water resistance (water resistance) increases the felt surface slippery feeling, reduce dust adhesion, easy to blow ash.

Product detail pictures:

Related Product Guide:

Assume full duty to satisfy all demands of our clients; reach steady advancements by marketing the development of our purchasers; grow to be the final permanent cooperative partner of clientele and maximize the interests of customers for 100% Original Factory Duplex Lamination Machine - High Efficiency Filter Material laminating machine for Filter Bag Dust Bag – Yuanhua , The product will supply to all over the world, such as: Malta, Lithuania, New Zealand, In order to meet more market demands and long-term development, a 150, 000-square-meter new factory is under construction, which will be put into use in 2014. Then, we shall own a large capacity of producing. Of course, we will continue improving the service system to meet the requirements of customers, bringing health, happiness and beauty to everyone.

We have worked with many companies, but this time is the best,detailed explanation, timely delivery and quality qualified, nice!