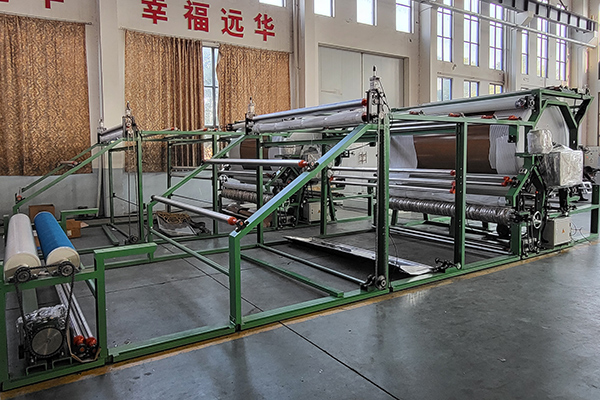

Laminators have become critical tools in industries ranging from printing to packaging. They protect and enhance the appearance of documents and other materials with a transparent protective layer. Among the wide variety of laminating machines on the market, the vertical belt water glue laminating machine stands out with its ten major features.

The first feature that sets this laminator apart is that it uses water-based glue or white latex. This allows the machine to produce high-quality laminates without the use of harsh chemicals typically used with other types of glue. Not only does this make the final product more environmentally friendly, but it also ensures a strong bond that will stand the test of time.

In addition to its adhesive selection, the vertical belt-type water-adhesive laminating machine greatly improves the overall quality of the laminate product while saving costs. Due to its vertical structure, it has a lower failure rate and longer service life than other machines on the market. This means businesses can rely on this machine for consistent and reliable performance, allowing them to focus on core operations without the hassle of frequent repairs or replacements.

One of the key features of this laminator is its ability to increase drying efficiency. Equipped with high-quality heat-resistant mesh belt to keep the laminated material in close contact with the drying cylinder. This improves drying, resulting in a soft and well-bonded final product. This not only improves the aesthetics of the laminates, but also enhances the bond strength, making them more durable and long-lasting.

Energy consumption is a concern for many companies. The vertical belt-type water glue laminating machine solves this problem by providing two sets of heating systems. Users have the flexibility to choose one or two heating modes to reduce energy consumption and costs based on their specific requirements.

Uneven heating can lead to poor lamination results, which is why the surface of the heating roller in this machine is coated with Teflon paper. This coating effectively prevents uneven heating, ensuring consistent and high-quality lamination performance every time.

Adjustability is another great feature of this laminator. The nip rollers are easily adjustable using handwheels or pneumatically controlled for precise control of the lamination process. This ensures that the laminate is produced with the required thickness and pressure, resulting in superior quality.

To enhance user experience and prevent any operational issues, the machine is equipped with automatic infrared centering control. This device effectively prevents the mesh belt from deflecting and ensures the service life of the mesh belt. This not only saves costs but also ensures long-term stable performance.

The vertical belt water glue laminating machine can also be customized. Companies can customize the machine's structure to suit specific material properties and customer needs. This level of customization allows for greater versatility and adaptability, making the machine suitable for a wider range of applications.

Finally, maintenance costs and ease of maintenance are key considerations for any machine. The vertical belt water-glue laminating machine has extremely low maintenance costs and is simple to maintain. Additionally, it offers simple and intuitive operation, allowing users to start laminating quickly and efficiently.

In summary, the ten features of the vertical belt water glue laminating machine make it the best choice for companies that require reliable and high-quality composite materials. From the use of environmentally friendly adhesives to the customizable construction, the machine delivers the perfect balance of performance, cost-effectiveness and user-friendliness. Investing in a vertical belt hydrogel laminator can revolutionize your laminating operation, improve the quality of your products and maximize the potential of your business.

Post time: Aug-31-2023