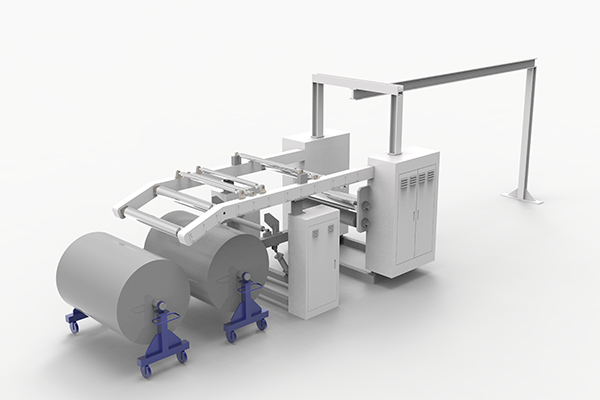

2022 High quality Water Glue Base Laminating Machine - High Efficiency PU Glue, Hot Melt Glue Dual-Use Laminating Machine for Textile,Fabric,Sponge, Foam,Clothes,Nonwoven Fabric Lamination – Yuanhua

2022 High quality Water Glue Base Laminating Machine - High Efficiency PU Glue, Hot Melt Glue Dual-Use Laminating Machine for Textile,Fabric,Sponge, Foam,Clothes,Nonwoven Fabric Lamination – Yuanhua Detail:

Product Presentation

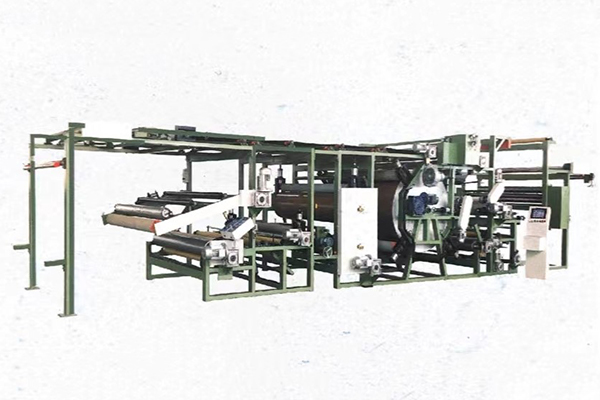

Can use oil glue composite, can use environmentally friendly hot melt glue composite.The use of hot melt glue composite requires heating on the glue device, through the knife body in the heated heat conduction oil circulation.Can achieve the purpose of environmental protection, but also can save the cost of machines.Is the current product of small and medium-sized compound factory.

Hot melt glue composite machine is used in clothing leather, sole shoes, light foam sheet composite processing, its advantage is that PE film instead of glue fit, product inventory time, no color signs, not easy to tear open, joint effect is stronger than glue, has excellent adaptability and stability, combining speed control circuit, automatic temperature control circuit, can be thick but thin fit, convenient and accurate control production and composite quality, count code, is the ideal composite equipment.The machine has many advantages of novel structure, simple operation, low failure rate and long service life.

PU glue, hot melt glue dual-use composite machine characteristics

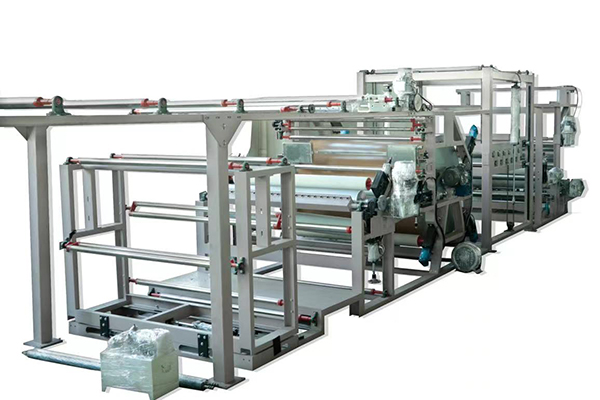

Using the glue point transfer technology, the glue is evenly transferred to the cloth or film, and combined with the surface cloth to form an integration. The composite fabric has the characteristics of water resistance, dry cleaning, sand washing, waterproof and wetting function.The rear upper cloth adopts open width, center and blowing system; there has automatic edge suction device.The whole machine adopts gear transmission PLC control, with high accuracy and good synchronous performance.Two methods are surface winding and large winding loading.

PU glue, hot melt glue dual-use composite machine use

PU glue, PUR hot melt glue dual-use composite machine can use both solvent type glue but also use solvent-free environmental protection PUR hot melt glue, can fit cloth + cloth, cloth + film and other market required composite materials.Composite finished products have the characteristics of environmental protection and non-toxic, good adhesion and softness, high and low temperature resistance, not susceptible to temperature after moisture reaction, durable elasticity, oil resistance, anti-aging and so on.In addition, PUR has excellent fog surface efficiency, low precipitation substance and neutral color characteristics, which can be applied to medical products that must be repeated disinfection.The finished product combined with PUR hot melt glue composite machine has a low loss rate and a high water washing fastness.PUR hot melt glue composite machine can replace the traditional solvent type fitting equipment, production without flammable, explosive and toxic solvent glue, the factory has no safety risks, meet the safety department requirements; can make the production workers away from the solvent to the body, composite finished products without solvent residue, meet the export environmental protection standards, has great social benefits.

PU glue, hot melt glue dual-use composite machine industry application

Technical parameters of PU glue and hot melt glue

|

Effective range |

1600 mm |

|

Mechanical roller width |

1800mm |

|

Design line speed |

5-45m/min |

|

Mechanical external dimensions (length * width * height) |

11000×2350×2200 mm |

|

Heating temperature of thermal conductive oil |

Adjustable heat oil cycle of 180℃ (MAX) |

|

Total mechanical power |

About 40KW |

|

supply of power |

380V 50Hz Three-phase |

|

gross weight of equipment |

About 6,500 K G |

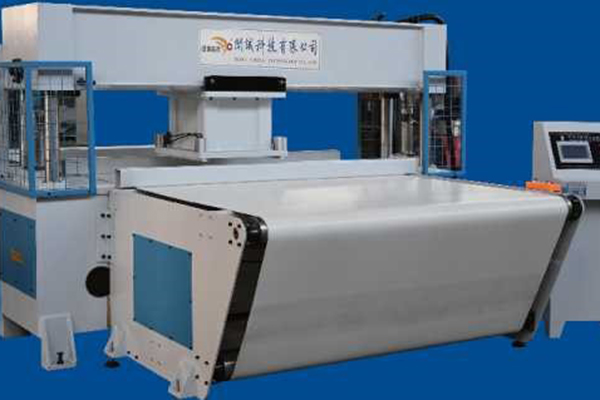

Product detail pictures:

Related Product Guide:

We also offer you product sourcing and flight consolidation expert services. We've our personal manufacturing unit and sourcing business. We can offer you virtually every variety of merchandise associated to our item range for 2022 High quality Water Glue Base Laminating Machine - High Efficiency PU Glue, Hot Melt Glue Dual-Use Laminating Machine for Textile,Fabric,Sponge, Foam,Clothes,Nonwoven Fabric Lamination – Yuanhua , The product will supply to all over the world, such as: Ireland, Leicester, moldova, Why we can do these? Because: A, We are honest and reliable. Our items have high quality, attractive price, sufficient supply capacity and perfect service. B, Our geographical position has a big advantage . C, Various types: Welcome your inquiry, It might be highly appreciated.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!